Processing and Marketing of Selected Cassava Products in South-east Nigeria

Dr. Ikechi Agbugba | Contributor on Agribusiness Topics

Stella O. Ani, Ikechi K. Agbugba and Lloyd J.S. Baiyegunhi, Department of Agricultural Economics Faculty of Agriculture University of Nigeria, Nsukka, Nigeria, Discipline of Agricultural Economics, School of Agricultural Earth and Environmental Sciences University of KwaZulu-Natal South Africa.

ABSTRACT The study investigates the processing and marketing of cassava products in the Southeast, Nigeria. Multistage random sampling was used to select 120 respondents, using structured questionnaire to collect primary data on the quantity and the cost of cassava used for processing each product, the method of processing and cost of processing. The return per naira on investment of the cassava products was evaluated, and the result showed that cassava processing is a profitable venture.

Want to learn more about storytelling? Start by downloading the first chapter of The Storytelling Mastery.

Processing cassava tubers into flour was more profitable with a return of 9kobo per N1 invested in the business as against 7.8kobo and 7.1kobo for garri and chips respectively. Several constraints associated with processing and marketing of cassava products were identified.

This study recommended the need for government and the private sector to assist cassava processors with credit, processing and storage facilities, and good road network as this will boost the economic performance of this sector of the economy.

KEYWORDS Processing. Marketing. Cassava Product. South-east. Nigeria

Introduction

Cassava is one of the world’s most important food crops with an annual output of over 34 million tonnes of tuberous roots (Asogwa et al. 2013). Throughout the tropics, its roots and leaves provide essential calories and income.

Africa is one of the continents of the world where some 600 million people are dependent on cassava for food (International Fund for Agricultural Development (IFAD) 2013). Cassava is produced largely by small-scale farmers using rudimentary farm implements and most of the cassava produced is used for human consumption with less than 5% is used in industries.

Cassava per capita consumption is very high and provides about 80 % of the total energy intake of many Nigerians (Ani 2010). As a food crop, cassava fits well into the farming systems of the smallholder farmers in Nigeria because it is available all year round, thus ensuring household food security.

Compared to grains, cassava is more tolerant to low soil fertility and more resistant to drought, pests, and diseases (Obisesan 2012). Its roots store well in the ground for months after maturity (Ope-Ewe et al. 2011).

See also Cassava Farming in Nigeria – A Gateway to Agribusiness Success for the African Diaspora

Cassava production industry in Nigeria is increasing at 3% per annum but the importation of starch, flour, sweeteners that can be made from cassava continues. About one-third of the total national output comes from the Niger Delta region where many households depend on it as a main source of food and income.

It has been estimated that the number of small commercially oriented cassava producers within the region would be in the range of 70,000-120,000 (out of the more than 1 million producers) and over 400500 cooperatives and cottage industries, 800,000-950,000 traders, 46 small medium processing industries and 1 large processing industry in the region (Nigeria Bureau of Statistics 2008).

Apart from livestock feeds, processed cassava serves as industrial raw material for the production of adhesives, bakery products, dextrin, dextrose glucose, lactose and sucrose. Food and beverage industries use cassava products in the production of jelly caramel and chewing-gum, pharmaceutical and chemical industries also use cassava alcohol (ethanol) in cosmetic and drug production.

Cassava cubes are used mainly in the compounding of livestock feeds. Thus there is a very high demand for cassava products both in local and foreign markets (Foundation for Partnership Initiatives in the Niger Delta, Foundation for Partnership Initiatives in the Niger DeltaPIND 2011; AdulAzeez 2013).

According to FAO (2011), cassava is important, not just as a food crop but as a major source of cash income for producing households. As a cash crop, cassava generates cash income for the largest number of households, in comparison with other staples, contributing positively to poverty alleviation with other staples, contributing positively to poverty alleviation (Rural Sector Enhancement Programme 2002).

Hence, efficiency in cassava marketing is an important determinant of both consumers’ living cost and producers’ income and the potentials of cassava marketing to agricultural and overall economic development cannot be over-emphasized (Obisesan 2012).

The growth in cassava production has been primarily due to rapid population growth, large internal market demand, complemented by the availability of high yielding improved varieties of cassava, a relatively well-developed market access infrastructure, the existence of improved processing technology and a well-organized internal market structure (Onyinbo et al. 2011).

Women play a central role in cassava production, processing and marketing, contributing about 58 per cent of the total agricultural labour in the southwest, 67 per cent in the southeast and 58 per cent in the central zones (PIND 2011). They are almost entirely responsible for processing cassava, this provide additional income-earning opportunity as well as enhancing its ability to contribute to household food security (FMANR 2006).

The Federal Government’s policy of including cassava flour in bread and other confectioneries to substitute wheat flour has presented great opportunities for investors and farmers alike.

However, several constraints affect cassava processing which limit the contribution of the crop to the development of Nigeria’s economy (Adebayo and Sangosina 2005; Ntawuruhunga 2010). Boosting production without boosting of its marketing can lead to glut of cassava in the market. This can depress prices and discourage farmers from investing cassava cultivation (IFAD 2013).

Marketing can pose a problem for poor farmers who may not have resources to transport their commodities to the market, especially those living in villages with poor feeder roads.

Typically, farmers transport their farm produce to the market on heads as head loads, on bicycles or in lorries. With poor market access, marketing of cassava can be particularly problematic because of its bulky nature, especially if it is not processed (Cassava Report Final 2013).

Products derived from cassava include garri, starch, tapioca, fufu, pellets, flour and chip. However, this study focused on products derived from cassava roots which are: garri, chips and flour.

Cassava is produced mostly by smallholder farmers on marginal or sub-marginal lands of the humid and sub-humid tropics (Ani 2010). Such smallholder systems as well as other aspects of its production often create problems, including: the unreliability of supply, uneven quality of products, low producer prices, and an often costly marketing structure.

Thus, the challenge is to create a strategy that affects production, processing, and marketing in such a way that they provide an array of high-quality products at reasonable prices for the consumers, while still ensuring a good profit margin for the producers without requiring them to assume the largest part of the development risk (Ntawuruhunga 2010).

Objectives

The purpose of the study is to:

- describe the source of cassava tubers and method of processing into the selected cassava products (flour, chips and garri) in the study area;

- determine the returns per naira on investment of marketing of the selected cassava products

- describe the marketing channel of the selected cassava products;

- identify the constraints associated with processing and marketing of the selected cassava products.

Material And Methods

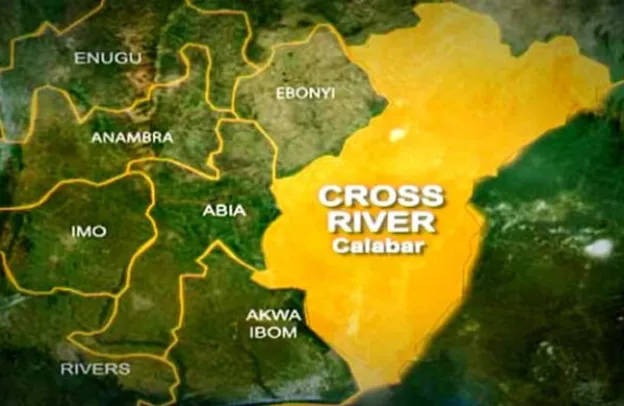

This study was conducted in Uzo-Uwani Local Government Area in Enugu State, South-East Nigeria. The area is made up of three (3) clans, Igboda, Mbanano and Ogboli, which comprises of sixteen (16) autonomous communities. It has a land area of 136.96km2 and a population size of 124,480 persons (National Population Commission 2006).

The area lies within longitudes 6045/ and 70 North, latitudes 7012/ and 360 East (Uzo-Uwani Local Government Bulletin 1990). There are primary feeder and terminal markets. The inhabitants are predominantly famers. This could be as a result of the natural endowment of a large expanse of fertile agricultural land.

A structured questionnaire was used to collect primary data on the quantity of cassava that was used for each product, method of processing, cost of processing the cassava, the cost of cassava that was used. Multi-stage random sampling was used to select the respondents in the study area. In first stage, two clans were purposively selected because they are predominantly involved in cassava processing.

In second stage, five communities were randomly selected from each of the two clans, while in the third stage, a census and listing of cassava processors and marketers in each of the communities was conducted through the Enugu State Agricultural Development Programme (ENADEP) officials, market associations and community leaders.

From the formed sampling frame, 24 respondents (that is, 12 processors and 12 marketers) were selected from each of the five communities, giving a total of 120 respondents.

Descriptive statistics such as frequencies and percentages were used to analyse the processing methods of selected cassava products (flour, chips and garri) in the study area, the constraints associated with their processing and marketing, as well as their channel of marketing. Rate of returns per naira on investment was used to analyse the returns on investment of marketing of the selected cassava products. Rate of Return on Investment (RRI)

This is specified as:

Net Income (NI)

RRI =

Total Cost (TC)

where; N I = TR-TC TR = Total revenue from the cassava products aforementioned

TC = TFC + TVC = Total cost of cassava products (garri, chips and flour)

TFC = Total fixed cost such as cost of frying pan, sieve, bags, frying spoon, tripod stands, knives, etc.

TVC = Total variable cost such as cost of fresh tuber, cost of transportation, cost of firewood, labour cost, cost of oil, etc.

TC = Total Variable Cost (TVC) + Depreciation

Total Cost of assets – Salvage value

Depreciation =

Useful life

Results And Discussion

Source of Cassava Tubers

Cassava processors in the study area obtained their cassava tubers from four main sources. These are farm gate, wholesalers, retailers and the processors’ own farm. The distribution of respondents according to the source of cassava is presented in Table 1.

Table 1 shows that about 36% of the respondents source their cassava tubers for processing into garri, chips and flour from the farm gate, while about 27% source their cassava tubers from wholesalers. About 23% source their cassava tubers from retailers while 15% source their cassava tubers from their own farm.

Table 3 further revealed that 40% of respondents who processed cassava into garri sourced their cassava tubers from the farm gate while 20%, 25% and 15% sourced cassava tubers from wholesalers, retailers and own farm respectively.

For those who processed into chips, about 38% sourced cassava tubers from farm gate, while 35%, 15% and 13% sourced cassava tubers from wholesalers, retailers and own farm respectively. And for those who processed into flour, 30% sourced cassava tubers from farm gate, while 25%, about 28% and 18% sourced cassava tubers from wholesalers, retailers and own farm respectively.

Method of Processing Cassava Product

Processing of cassava is very important because the root is made up of about 60-70 percent water and has a shelve life of 2-3 days. Processing, therefore, reduces the water content and converts it into a more durable and stable product, thereby eliminating the hydrocyanic acid

Table 1: Distribution of respondents according to the sources of cassava tubers

| No | % | No | % | No | % | No | % | No | % | |

| Garri | 16 | 40 | 8 | 20 | 10 | 25 | 6 | 15 | 40 | 33.33 |

| Chips | 15 | 37.5 | 14 | 35 | 6 | 15 | 5 | 12.5 | 40 | 33.33 |

| Flour | 12 | 30 | 10 | 25 | 11 | 27.5 | 7 | 17.5 | 40 | 33.33 |

| Total | 43 | 35.83 | 32 | 26.67 | 27 | 22.5 | 18 | 15 | 120 | 100 |

Source: Field Survey 2010

Table 2: Distribution of respondents according to the method of cassava processing

Traditional Mechanical Total

| No | % | No | % | No | % | |

| Garri | 35 | 87.5 | 5 | 12.5 | 40 | 33.33 |

| Chips | 32 | 80.0 | 8 | 20 | 40 | 33.33 |

| Flour | 31 | 77.5 | 9 | 22.5 | 40 | 33.33 |

| Total | 98 | 81.67 | 22 | 18.33 | 120 | 100.00 |

Source: Field Survey 2010

content. Two methods are usually used for cassava processing; these are the tradition and mechanical methods. The traditional method involves fermentation and dewatering (pressing), which are done in one operation, while in the mechanical method, the processes are done separately. The distribution of respondents according to the methods of processing cassava is presented in Table 2.

Table 2 shows that 87.5% and 12.5% of the respondents were using traditional method and mechanical method for processing cassava to garri, respectively, while 80% and 20% of the respondents were using traditional method and mechanical method for processing cassava tubers into chips. Similarly, 77.5% and 22.5% of the respondents were using traditional and mechanized method for processing cassava into flour respectively.

Majority of the respondents still depend largely on traditional method for processing cassava, although they used hydraulic press and grater for dewatering and crushing of the cassava tubers into pulp. Only few respondents use mechanized method of processing. This may be due to the high cost of mechanized processing machine.

Duration of Processing Cassava (In Days)

Fermentation of grated mash is very important for the detoxification of the poisonous cyanide content in cassava. The longer the duration of fermentation, the lesser the cyanide content of garri, chips and flour. However, an optimum duration period of 3-5 days has been recommended. The distribution of respondents according to the duration of processing cassava is presented in Table 3.

Table 3 revealed that out of the 40 garri processors in the study area, 35% processed their cassava within 2 days, 52.5% processed within 3 days, while 10% processed within 4 days.

See also Cassava Farming in Nigeria – A Gateway to Agribusiness Success for the African Diaspora

The large market value and demand for the commonly processed products from Uzo-Uwani may have resulted in 35% of processors processing their cassava (mash fermentation) within 2days instead of the recommended 3-5 days to make more money thus sacrificing safety.

The result from Table 3 further shows that for chips processing, 2.5% of the respondents process their cassava tubers within 3 days, while 25%, 32.5%, 37.5%, 2.5% processed within 5,6,7 and 9 days, respectively. Similarly for flour processing, 10%, 42.5%, 45%, 2.5% processed their cassava tubers within 5, 6 and 9 days respectively.

The above result shows that flour and chips processing is more time consuming than garri processing. Hence, the garri processors processed large quantity of the product as compared to chips and flour. This generates more turn-over, since garri is apopular household staple food in Nigeria.

Cassava Products Marketing Channel

| Table 3: Distribution of respondent according to the duration of processing (in days) |

The marketing channel identified for the cassava products is depicted by Figure 1. The processed cassava products moved from the producers to the wholesalers, from the wholesalers to retailers and from the retailers to the final consumers (households, hotels, cooks, etc.) consumers through marketing channel.

Cassava Processors —> Wholesalers —> Retailers —>

Consumers

Fig. 1. Cassava-Product Marketing Channel

Rate of Return in Investment in Processing and Marketing of the Cassava Products

Returns per naira invested in the cassava products were evaluated by computing the rate of investment for each of the processed cassava product that was produced and marketed by the respondents to get the net income, this was divided by the total cost.

The item associated with the variable cost of the enterprise includes, cost of fresh tuber, cost of transportation, cost of firewood, and cost of palm oil. Total fixed costs which are associated with frying pans, sieves, machetes, sack bags, knives, basins, wooden stares and frying spoons. The straight line method was used in calculating the depreciated values of the equipment used.

The rate of returns per Naira invested in processing N 10,000 worth of Cassava tubers (5000kg) to the Cassava products is presented in Table 4.

The result in Table 4 shows that 5000kg of cassava tubers used to produce garri will costs about N 10,000 at average price of N 250 per kg. The labour cost and the depreciation of the equipment used was N 4,400 and N 850 respectively, giving a total cost of N 17,550 for processing cassava tubers into garri.

The total revenue was N 31,200, with a gross margin of N 13,350. For processing cassava tubers into chips, N 10,000 (5000kg) worth of cassava tubers were processed at an average price of N 250 per kg, with the labour costing N 4,600 and depreciation on equipment used at N 1,180.

The total cost incurred by the processors was N 17,500 with total revenue of N 30,000 and a gross margin of N 12,500. While to process cassava tubers into flour, the table showed that N 10,000 (5000kg) worth of cassava tuber was used to produce cassava flour at the average price of N 250 per kg. The respondent incurred a depreciation of N 925. The total cost of processing was N 30,500, with a gross margin of N 14,425.

The study revealed that labour and cassava tuber are the most cost item in cassava processing, while the depreciation cost was the least. However, the result of the rate of returns of investment shows that cassava processing is an income earning venture.

The return per naira of investment on the processing of N 10,000 worth of cassava tuber into different products gave 7.8 kobo for garri, 9 kobo for flour and 7.1 kobo for chips. This implied that for every N 1 invested in garri, flour and chip processing, it yielded the sum of 7.8 kobo, 9 kobo and 7.1 kobo respectively.

The result further indicates that processing cassava tubers into flour is more rewarding since the return to investment is higher for flour compared to garri and chips.

Constraints in Cassava Product Processing and Marketing

Cassava processing and marketing can be faced with much drudgery thereby limiting the ability of the processors to improve their pro-

Table 4: Returns per Naira (M) invested in processing N 10,000 worth of cassava tubers (5000kg) to the cassava products

| Item | Average | Quantity | Value | (K) | Value | (K) | Value | (K) | |

| price | for | for | for | ||||||

| garri (N) | flour (N) | chips (N) | |||||||

| Total revenue | 31,200 | 30,400 | 30,000 | ||||||

| Variable cost of inputs (cassava tubers) | 250 | 5,000kg | 10,000 | 10,000 | 10,000 | ||||

| Palm oil | 5 Litres | 850 | |||||||

| Labour for processing cassava products | 4,400 | 3,650 | 4,600 | ||||||

| Transport cost | 1,450 | 1,400 | 1,650 | ||||||

| Total variable cost of cassava products | 16,700 | 15,050 | 16,320 | ||||||

| Depreciation of fixed cost | 850 | 925 | 1,180 | ||||||

| Total cost | 17,550 | 15,975 | 17,500 | ||||||

| Net income | 13,650 | 14,425 | 12,500 | ||||||

| Return per Naira on investment | 7.8 | 9 | 7.1 | ||||||

Source: Field Survey 2010. Note: $1 = N 156

Table 5: Distribution of respondents by constraints to cassava processing

| S. | Constraints | 4 | 3 | 2 | 1 | Σfx | X | Remarks |

| No. | SA | A | SD | D | ||||

| 1. | Lack of finance | 87 | 30 | 3 | 0 | 444 | 3.7 | Agreed |

| 2. | Lack of processing facilities | 33 | 60 | 15 | 12 | 354 | 2.95 | Agreed |

| 3. | Sourcing of labour | 35 | 45 | 36 | 4 | 351 | 2.93 | Agreed |

| 4. | Marketing problems | 54 | 27 | 24 | 15 | 360 | 3.0 | Strongly Agreed |

| 5. | Transportation Problems | 69 | 21 | 12 | 18 | 456 | 3.8 | Agreed |

| 6. | Inadequate storage facilities | 21 | 42 | 48 | 9 | 315.6 | 2.63 | Agreed |

Source: Field Survey 2010

techniques and activities; reduce their level of participation and marketing of products; and consequently, retard the expansion on investment on the processing business.

See also A Comprehensive Guide for Data and Monitoring Systems in Cassava Farming

The major constraint to cassava processing and marketing includes: lack of finance, lack of processing facilities,sourcing of labour, marketing problems, transportation problems and inadequate storage facilities. Table 5 represents a rating for the constraints by summing up the responses and multiplying by the average of the respondents.

Table 5 shows that lack of finance ranging from capital to start and maintaining a business, credits and collateral; coupled with high interest rates are major constraints (3.7) to processing of cassava. Processing facilities are usually expensive, and lack of it resulted in majority of the respondents using traditional processing methods.

Sourcing for labour also constitutes a major constraint (2.93) by the respondents, as labour for cassava processing is very expensive. Marketing problems was identified and agreed (3.0) by the processors as a major constraint.

There is no standard pricing or grading systems for the processed products. This had led to low income from the processed products, hence discouraging further investment. Also, transportation problems (3.8) affect cassava products processing.

The bad condition of the rural roads makes transportation of fresh cassava tubers and products difficult, since it affects gross margins. Another constraint identified is inadequate storage facilities (2.63). An inadequate storage facility limits the growth, development and expansion of the processing enterprise.

Conclusion And Policy Implications

Cassava has been noted to be a cash crop and Nigeria, recognized globally as highest producer. Cassava crop has become prominent in Nigeria’s drive towards increasing her foreign exchange base, and serves as one of the major sources of carbohydrate while commercialization of its processing contributes to poverty reduction and sustains livelihoods due to its income generating potential.

Findings from the study have showed that processing and marketing of the selected cassava products (garri, chips and flour) is a profitable business venture. There is need therefore, to scale up cassava processing and expand the industry for opportunities income generation for the rural populace, as well as to achieve the target of the presidential initiative on cassava production and export.

There is need for the provision of improved processing techniques to eliminate drudgery, wastefulness and low productivity associated with traditional processing.

Government as well as private sectors’ indispensable role in providing cassava processors access to resources needed to acquire and maintain innovations cannot be over emphasized. Credit facilities, appropriate energy sources and trained personnel should be made available within reach to processors and marketers of cassava products.

See also Amaka Ifeduba on Agricultural Development and Youth Empowerment

Finally, market opportunities can be fully developed through provision of adequate infrastructures such as good roads, pipe borne water, modern market and processing centres, as well as efficient transport and communication system. Such development will boost both domestic and export market for garri, flour and chips as well as other processed cassava products.

References

Abdul Azeez I 2013. Cassava Export and Local Utilization in Nigeria Top Secrets. The Consulting, Thursday May 30th, 2013.

Adebayo K, Sangosina MA 2005. Perception of the Effectiveness of Some Cassava Processing Innovation in Ogun State. Proceedings of 19th Annual Conference of Farm Management Association of Nigeria held at Delta State University, Asaba Campus18th– 20th October,pp. 234-235.

Ani SO 2010. Comparative Economic Analysis of Selected Cassava Derivatives in Uzo-Uwani Local Government Area of Enugu State. MSc Research Work, Unpublished. Department of Agricultural Economics, University of Nigeria, Nsukka.

Asogwa BC, Ezihe JAC, Ater PI 2013. Socio-economic analysis of cassava marketing in Benue State, Nigeria.

International Journal of Innovation and Applied Studies, 2(4): 384-391.

Cassava Report Final 2013. Action Plan for a Cassava Transformation in Nigeria. From <www.unaab.edu. ng/attachments/Cassava%20Report%20Final.pdf> (Retrieved on 27 June 2013).

FAO 2011.Strengthening Capacity for Climate Change Adaptation in the Agriculture Sector in Ethiopia,

Proceedings from National Workshop held in

Nazareth,Ethiopia 5th-6th July, 2010,(Climate Change

Forum, Ethiopia) organized by Climate, Energy and Tenure Division Natural Resources Management and Environment Department Food and Agriculture Organization of the United Nations, Rome, Italy.

Federal Ministry of Agriculture and Natural Resources (FMANR) 2006. Cassava Development in Nigeria: A Country Case Study Towards a Global Strategy for Cassava Development Prepared by Department of Agriculture, Federal Ministry of Agriculture and Natural Resources. From <ftp://ftp. fao.org/docrep/ fao /009/A0154E/A0154E02.pdf> (Retrieved on 27 June 2013).

Foundation for Partnership Initiatives in the Niger Delta, PIND 2011. A Report on Cassava Value-Chain Analysis in Niger Delta. From <www.pind foundation.net/ wp-content/pluggins/Cassava-Value-Chain-Analysis. pdf> (Retrieved on 26 June 2013).

International Fund for Agricultural Development 2013.Cassava: Turning a Subsistence Crop into a

Cash Crop in Western and Central Africa, Rural Poverty Portal, BreadcrumbsPortlet, Powered by IFAD.From <http://www.fidafrique.net/rubrique554. html> (Retrieved on 27 June 2013).

Nigeria Bureau of Statistics 2008. Nigeria Annual Abstract of Statistic. Federal Republic of Nigeria, Abuja.

Ntawuruhunga P 2010. Strategies, Choices, and Program, Priorities for the Eastern African Root Crops Research Network. EARRNET Coordination Office, IITA Uganda.

Obisesan AA 2013. Credit accessibility and poverty among smallholder cassava farming households in southwest Nigeria. Greener Journal of Agricultural Sciences, 3(2): 120-127.

Onyinbo O, Damisa MA, Ugbabe OO 2011. An Assessment of the Profitability of Small-scale Cassava Production in Edo State: A Guide to Policy. From <www. academia.edu/1995/84_/AN_ASSESSMENT_OF_ THE_PROFITABILITY_OF_SMALL_SCALE_CASSAVA_ PRODUCTION_IN_EDO_STATE_A_GUIDE_

TO_POLICY> (Retrieved on 28 June 2013).

Ope-Ewe OB, Adetunji MO, Kafiya MR, Onadipe OO, Awoyale W, Alenkhe BE, Sanni LO 2011. Cassava Value Chain Development by Supporting Processing and Value Addition by Small and Medium Enterprises in West Africa – Nigeria. Technical Report August 2008 – August 2011.

Uzo-Uwani Local Government Area Bulletin 1990. Umulokpa. Uzo-Uwani, Enugu State.

Want to learn more about storytelling? Start by downloading the first chapter of The Storytelling Mastery.