11 Great Industrial Uses Of Cassava You Didn’t Know Of

Want to learn about the industrial uses of cassava? You are in the right place. Cassava starch, known for its high purity, has a wide range of uses, particularly when it is modified, hydrolyzed, and derivatized through physical, chemical, and enzyme processes. This makes it suitable for a variety of applications, including food, paper, textile, adhesive, pharmaceutical, cosmetics, and chemical products.

Learn How to Leverage Your Story through our Story To Asset Framework.

Cassava is a versatile crop with a wealth of industrial uses, primarily due to its high starch content. The roots are processed to extract this starch, which becomes a key ingredient in a variety of industries.

From food production to pharmaceuticals, textiles, and paper, cassava starch serves as a thickener, stabilizer, and binder in countless products. In this article, we will dive into 11 surprising and lesser-known ways cassava is being used across industries. Prepare to discover the incredible impact of this humble root.

Manufacturing products is half the battle. Owning the system is how you build a permanent empire.

Cassava is used for food production

Cassava is a key ingredient in many traditional dishes such as fufu, garri, and tapioca. It is also used to make flour, which is used to make bread, noodles, and other foods.

Cassava is a staple food in many parts of the world and is used in a variety of ways in food production. Some of the most common ways it is used include:

- Cassava flour: Cassava flour is made by grating, washing, and drying the root. This flour can be used as an alternative to wheat flour, making it a gluten-free option. It is commonly used to make bread, noodles, and other foods.

- Fufu: Fufu is a traditional dish that is made by boiling and mashing cassava, and then rolling it into balls. It is commonly eaten in West Africa and parts of Central Africa as a staple food.

- Garri: Garri is another traditional dish that is made from cassava flour. It is prepared by fermenting, roasting, and grinding the root. The resulting powder is then formed into balls and eaten as a staple food in West Africa.

- Tapioca: Tapioca is a product made from cassava starch and is used to thicken puddings and pies, it is also popular in Asia to make cakes and snacks.

- Cassava Chips: Cassava is also used to make Cassava chips, it is deep-fried, it is a popular snack in some parts of Africa and Latin America.

- Cassava leaves: The leaves of the cassava plant can also be used to make a traditional dish, commonly consumed in Africa and Southeast Asia, where it is prepared by boiling and/or steaming them.

Cassava is an important food crop in many parts of the world because it is a hardy crop that can grow in poor soil and with minimal rainfall.

See also Cassava Starch: A Golden Opportunity for African Entrepreneurs in the Global Agribusiness Landscape

It is also a good source of carbohydrates and contains small amounts of vitamins and minerals. However, it’s worth noting that it’s important to prepare it properly to remove the cyanide and to ensure that it’s safe to eat.

Cassava is used for animal feed

Cassava leaves and peelings can be used to make animal feed, which is particularly useful for poultry, pigs, and fish.

You might also like Feeding the Future: How Diaspora Entrepreneurs Can Tap into Nigeria’s Cassava Potential for Agribusiness Success

Cassava can be used as an ingredient in animal feed, which is particularly useful for poultry, pigs, and fish. It is rich in carbohydrates and also contains small amounts of proteins and essential minerals, making it a valuable addition to animal feed.

- Cassava leaves: Cassava leaves are rich in protein and minerals such as calcium, phosphorus, and potassium, making them valuable ingredients in animal feed. They are commonly used to feed ruminants, pigs, and poultry. They can be fed fresh or dried.

- Cassava Peelings: Cassava peelings, a by-product from the processing of cassava into flour or starch, are also used as a source of feed for livestock. They are rich in carbohydrates and can be fed fresh or dried.

- Cassava Pulp: Cassava pulp, obtained from the grating of the root, can also be used as a source of animal feed. It’s particularly useful as a feed ingredient for swine and poultry.

- Cassava Cake: Cassava cake, a by-product from the extraction of starch, is a high-energy feed ingredient. It is rich in carbohydrates and can be fed to livestock, especially ruminants.

It is worth noting that before using cassava as animal feed, it should be processed properly to remove the cyanide so that it’s safe for the animals to consume. Additionally, too much of it in the feed could have negative effects on the animals’ health.

It’s always recommended to mix it with other feed ingredients for a balanced diet for the animals.

In summary, Cassava is a valuable ingredient in animal feed. It can be used as a source of carbohydrates, protein, and essential minerals for poultry, pigs, and fish. Cassava leaves, peelings, pulp, and cake are all used as feed ingredients for livestock.

It is an important feed ingredient for many farmers and can be used as a cost-effective way to feed animals. Proper processing of the cassava and including it as part of a balanced diet is important for the animal’s health.

Cassava can be used for Ethanol production

Cassava can be used to make ethanol, a biofuel that can be used as a gasoline additive or as a source of electricity.

See also Nigerian Cassava Production: How to Transform a Staple Crop into Africa’s Economic Powerhouse

Cassava can be used to make ethanol, which is a biofuel that can be used as a gasoline additive or as a source of electricity. Ethanol production from cassava is a process that involves the fermentation of the starch present in the root of the plant.

- Cassava starch extraction: The first step in the process is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities. The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Fermentation: The starch is then fermented by adding enzymes and microorganisms, such as yeast. The fermentation process converts the starch into sugars which are then converted into ethanol by a process called distillation.

- Distillation: The fermented liquid is distilled to separate the ethanol from the water and other impurities. The ethanol is then collected and purified through a process of rectification, to produce a high-purity product.

- Purification: The final product is then purified to remove any remaining impurities, such as methanol, that could negatively affect the quality of the fuel.

Glucose and fructose production

Cassava can be used to make glucose and fructose, which are sweeteners used in food and beverage production.

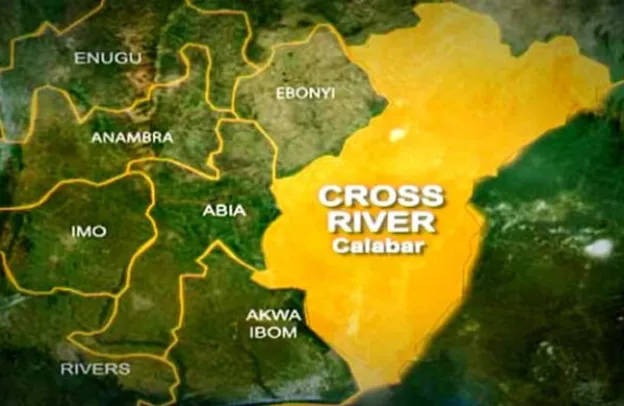

See also Processing and Marketing of Selected Cassava Products in South-east Nigeria

Cassava can be used to make glucose and fructose, which are sweeteners used in food and beverage production. The process of making glucose and fructose from cassava involves breaking down the starch in the root into simple sugars.

- Cassava starch extraction: The first step is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities. The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Enzyme hydrolysis: The starch is then broken down into simple sugars through a process called enzyme hydrolysis. In this process, enzymes are added to the starch to break down the complex sugars into simple sugars such as glucose and fructose.

- Purification: The mixture of glucose and fructose is then purified through a process of separation and crystallization. This process removes any impurities and produces a high-purity product that can be used as a sweetener.

- Drying: The final product is then dried to remove any remaining moisture, to produce a dry powder that can be used as a sweetener.

It’s worth noting that, the process of glucose and fructose production from cassava has some limitations in terms of yield and cost.

The yield of glucose and fructose from cassava is lower compared to other feedstocks like corn and sugarcane, and the process is also relatively costly. Additionally, the process requires specialized equipment and skilled personnel to produce the sweeteners on a large scale.

In summary, Cassava can be used to make glucose and fructose, which are sweeteners used in food and beverage production.

The process involves the extraction of starch from the root, breaking down the starch into simple sugars through enzyme hydrolysis, purifying the mixture, and drying it to produce a dry powder that can be used as a sweetener.

The process has some limitations in terms of yield and cost, but it is still an alternative to producing these sweeteners from cassava.

Cassava usage for starch production

Cassava can be used to make starch, which is used in the production of paper, textiles, and other products.

See also Processing and Marketing of Selected Cassava Products in South-east Nigeria

Cassava can be used to make starch, which is used in the production of paper, textiles, and other products. The process of making starch from cassava involves extracting and purifying the starch from the root of the plant.

- Cassava Starch Extraction: The first step in the process is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities. The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Purification: The starch is then purified to remove any remaining impurities, such as proteins and fibers. This process is usually done through a series of washing, centrifugation, and drying steps.

- Drying: The purified starch is then dried to remove any remaining moisture, to produce a dry powder that can be used as a thickener, binder, or adhesive in various industries

- Modification: The starch can also be modified chemically to create different properties such as high-temperature resistance, viscosity, or transparency, which are useful in specific industrial applications.

It’s worth noting that the starch extraction process can have a significant environmental impact if not properly managed.

It generates wastewater with high organic content that can lead to eutrophication and groundwater contamination.

Also, the process can be energy-intensive, but improvements in technology and management practices are reducing the environmental impact.

In summary, Cassava can be used to make starch, which is used in the production of paper, textiles, and other products. The process involves extracting and purifying the starch from the root, drying it, and in some cases modifying it chemically.

Starch from cassava is versatile, it can be used as a thickener, binder, or adhesive, in various industrial processes. It’s important to properly manage the starch extraction process to minimize its environmental impact.

Cassava starch can be used for pharmaceutical products

Cassava starch is used to make pharmaceuticals, such as tablets and capsules, and can also be used as a binder in the production of pills.

Cassava starch can be used in the production of pharmaceuticals, such as tablets and capsules, and can also be used as a binder in the production of pills.

- Tablet production: Cassava starch can be used as a binder in the production of tablets. A binder is a substance that holds the active ingredient and other excipients together in a tablet. It is added in small amounts, usually around 5-10% of the tablet’s weight, to help the ingredients stick together.

- Capsule production: Cassava starch can be used as a filler in the production of capsules. A filler is a substance that is added to the active ingredient to increase its bulk and to help it flow better during the capsule-filling process.

- Pill binder: Cassava starch can also be used as a binder in the production of pills. The starch is added to the active ingredient to hold the pill together and to provide a smooth surface for coating.

- Extraction of substances: Cassava root, or its derivative starch, can also be used to extract certain substances with medicinal properties, such as anti-inflammatory compounds, or even certain enzymes.

It’s worth noting that before using Cassava starch in pharmaceutical products, it is important to ensure that the starch has been properly processed and purified to remove cyanide and any other impurities. Additionally, quality control measures should be in place to ensure that the starch meets the necessary specifications for pharmaceutical use.

In summary, Cassava starch can be used in the production of pharmaceuticals as a binder and filler in tablet, capsule, and pill production. Its properties can help to provide the necessary cohesion and flow during the production process.

It is also a source of extraction of certain compounds with medicinal properties. It’s important to properly process and purify the starch to ensure it’s safe for pharmaceutical use and to meet the necessary quality control specifications.

Cassava is used for industrial alcohol

Cassava can be used to make industrial alcohol, which is used in the production of cleaning agents, disinfectants, and other products.

Cassava can be used to make industrial alcohol, which is used in the production of cleaning agents, disinfectants, and other products.

See also The Economic Value Of Cassava Farming In Africa Today

The process of making industrial alcohol from cassava involves fermenting the root of the plant and distilling the fermented liquid.

- Cassava starch extraction: The first step in the process is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities. The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Fermentation: The starch is then fermented by adding enzymes and microorganisms, such as yeast. The fermentation process converts the starch into sugars, which are then converted into alcohol by a process called distillation.

- Distillation: The fermented liquid is distilled to separate the alcohol from the water and other impurities. This process is done in a distillation column where the alcohol is vaporized and condensed back into liquid form.

- Purification: The industrial alcohol is then purified to remove any remaining impurities, such as methanol, that could negatively affect the quality of the product.

- Denaturation: Industrial alcohol is toxic and can be dangerous if consumed, it is denatured by adding certain chemicals, so it becomes undrinkable and safer to handle,

It’s worth noting that while Cassava is a potential source of industrial alcohol, it may not be as efficient as other feedstocks like corn and sugarcane, which have higher sugar content and thus a higher potential for alcohol production.

However, cassava is more tolerant to drought and other environmental challenges, and it can be

Bioplastics can be made from cassava

Cassava can be used to make bioplastics, which are environmentally friendly alternatives to traditional plastics.

Cassava can be used as a source of material for bioplastics, which are plastics made from renewable, bio-based materials.

See also Why Do People Consume Cassava?

The process of making bioplastics from cassava involves extracting the starch from the root of the plant and then converting it into a polymer.

- Cassava starch extraction: The first step in the process is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities.

- The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Starch modification: The extracted starch must be modified to be transformed into a polymer. There are several methods to do this, but the most common is to add chemicals to the starch to change its chemical structure, making it more thermoplastic.

- Extrusion: After being modified, the starch is extruded, and it can be mixed with other bioplastic feedstocks, such as potato starch, to form a bioplastic. This process can produce pellets, fibers, and sheets.

- Compounding: Once in pellet form, it can be mixed with other ingredients such as pigments, fillers, or plasticizers.

- Thermoforming: The resulting mixture is then thermoformed, which is the process of heating the plastic and shaping it into the desired form, such as packaging, bags, and plates.

It’s worth noting that while bioplastics made from cassava have several advantages, such as being biodegradable and compostable, they may not be as strong or durable as conventional plastics.

Furthermore, the process of making bioplastics from cassava is still in the development stages and is not yet widely commercialized.

In summary, Cassava can be used as a source of material for bioplastics, which are plastics made from renewable, bio-based materials.

The process of making bioplastics from cassava involves extracting the starch from the root of the plant, modifying it, and then converting it into a polymer.

Bioplastics made from cassava are biodegradable and compostable, but they may not be as strong or durable as conventional plastics. The process of making bioplastics from cassava is still under development and not yet widely commercialized.

Cassavas are useful for textile production

Cassava can be used to make textile fibers, which can be used to make clothing, bags, and other products.

See also Nigerian Cassava Production: How to Transform a Staple Crop into Africa’s Economic Powerhouse

Cassava starch can be used in the production of textiles, such as fabrics and yarns. The process of making textiles from cassava involves extracting the starch from the root of the plant and then converting it into a fiber.

- Cassava starch extraction: The first step in the process is to extract the starch from the root of the cassava plant. This can be done by grating the cassava and washing it to remove impurities. The starch is then separated from the rest of the root through a process of settling, centrifugation, and washing.

- Starch modification: The extracted starch must be modified to be transformed into a fiber. One way to do this is by adding chemicals to the starch to change its chemical structure and make it more thermoplastic.

- Spinning: The modified starch is then spun into fibers, similar to the process of spinning traditional fibers like cotton or wool.

- Weaving/knitting: The resulting fibers are then woven or knitted into fabrics or yarns, which can be used to make a variety of textile products.

It’s worth noting that while fabrics and yarns made from cassava starch may be a sustainable alternative, they may not be as strong or durable as those made from traditional fibers.

The process of making textiles from cassava starch is still in the development stages and is not yet widely commercialized.

In summary, Cassava starch can be used in the production of textiles, such as fabrics and yarns. The process involves extracting the starch from the root of the plant, modifying it, spinning it into fibers, and weaving or knitting it into fabrics or yarns.

While fabrics and yarns made from cassava starch may be a sustainable alternative, they may not be

Cassavas are used to make cosmetics

Cassava can be used as a source of ingredients in cosmetics, such as lotions, soaps, and shampoos. The root of the plant contains compounds that can be used in cosmetics for their moisturizing, soothing, and nourishing properties.

- Cassava extract: The root of the plant can be processed to extract certain compounds such as starch, glucose, and fructose that can be used as a base for lotions and other moisturizing cosmetics.

- Cassava root oil: Cassava root oil can be extracted from the root by cold-pressing or solvent extraction, it can be used as an emollient in cosmetics, and it gives a smooth and nourishing feeling to the skin and hair, while also providing moisture.

- Cassava leaf extract: Cassava leaves can be processed to extract certain compounds with anti-inflammatory and soothing properties, they can be used to reduce skin redness and inflammation.

- Cassava root powder: Ground root can also be used as a natural exfoliant in scrubs, soaps, and other cosmetics.

It’s worth noting that, not all cosmetics containing cassava ingredients are considered natural, as some products may be blended with synthetic ingredients or other chemical compounds to enhance their performance or stability.

Additionally, before using cassava ingredients in cosmetics, it is important to ensure that the root has been properly processed and purified to remove cyanide and other impurities, to ensure the safety of the final product.

You might also like The Nigerian Agricultural Renaissance: How You Can Fuel a Transformation in Agribusiness

In brief, cassava can be used as a source of ingredients in cosmetics such as lotions, soaps, and shampoos. It contains compounds that can be used for their moisturizing, soothing, and nourishing properties.

Cassava extract, root oil, leaf extract, and root powder are used in cosmetics, but it’s important to ensure that the root has been properly processed and purified before using it in cosmetics, to ensure safety and quality.

Cassavas are used in Biogas production

Did you know that cassava can be used to make biogas, which is a clean and renewable energy source?

It is worth noting that for these industrial uses, the Cassava is processed to remove cyanide and to ensure the starch/flour is of consistent quality. Also, for some of these industrial uses, some modified varieties of cassava are being used as well.

See also Why Cassava Is Considered A Sustainable And Drought-Resistant Crop

In summary, Cassava is a versatile and useful crop with many industrial uses. It is used in food production, animal feed, biofuel production, sweeteners, and various other industrial applications.

It is becoming an increasingly important crop due to its many uses and its sustainability as a crop. As the world’s population continues to grow, the demand for cassava is likely to increase, making it an important crop for farmers and industrialists alike.

Conclusion on the 11 industrial uses of cassava you didn’t know of Cassava

Welcome to the conclusion of this long article and I hope you get some value here.

Cassava is a versatile crop that has a wide range of industrial uses that many people may not be aware of. From producing biofuels, ethanol, and electricity to making animal feed, textiles, and paper, the potential of cassava as a raw material is vast.

The ability to produce ethanol from cassava makes it a valuable crop for biofuel production, while its high starch content makes it suitable for use in the production of adhesives, textiles, and paper.

See also Cassava Starch: A Golden Opportunity for African Entrepreneurs in the Global Agribusiness Landscape

The cyanogenic compounds in the root are also used in the production of pharmaceuticals, cosmetics, and pesticides, making it a valuable crop for both food and non-food uses.

The use of cassava in livestock feed can also improve food security and animal productivity. Additionally, its potential as a gluten-free alternative in baking and its value as a food source for malnourished people make it an important crop for improving global food security.

Moreover, cassava also has the potential to contribute to sustainable development and a circular economy as its by-products can be used in other industries.

However, its wide range of industrial uses also poses challenges such as the need for large-scale infrastructure to process and convert cassava into these products, and the competition with food and feed uses.

You might also like Nigerian Cassava Production: How to Transform a Staple Crop into Africa’s Economic Powerhouse

In conclusion, cassava is a valuable crop with a wide range of industrial uses, from biofuels and animal feed to textiles and paper. Its versatility, high yield per hectare, drought tolerance, and low input requirements make it a sustainable alternative in many industries.

Nevertheless, it is important to further research and develop ways to overcome the challenges in order to fully realize its potential in different industrial applications.

Learn How to Leverage Your Story through our Story To Asset Framework.